INTIMATE ARCHITECTURES AND HIDDEN SYSTEMS

Material and system analysis of the underwire bra

2020 | Academic | Independent Project

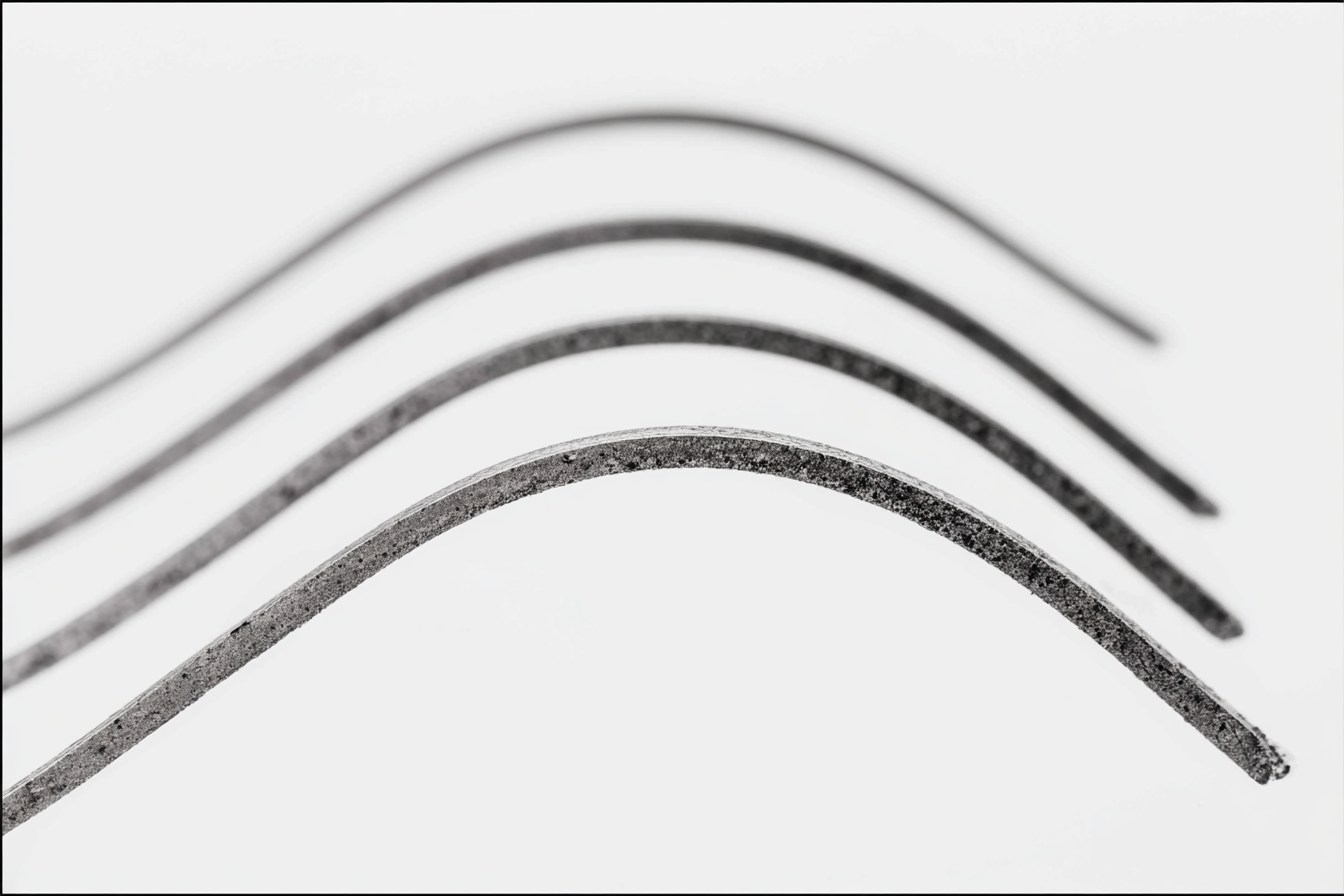

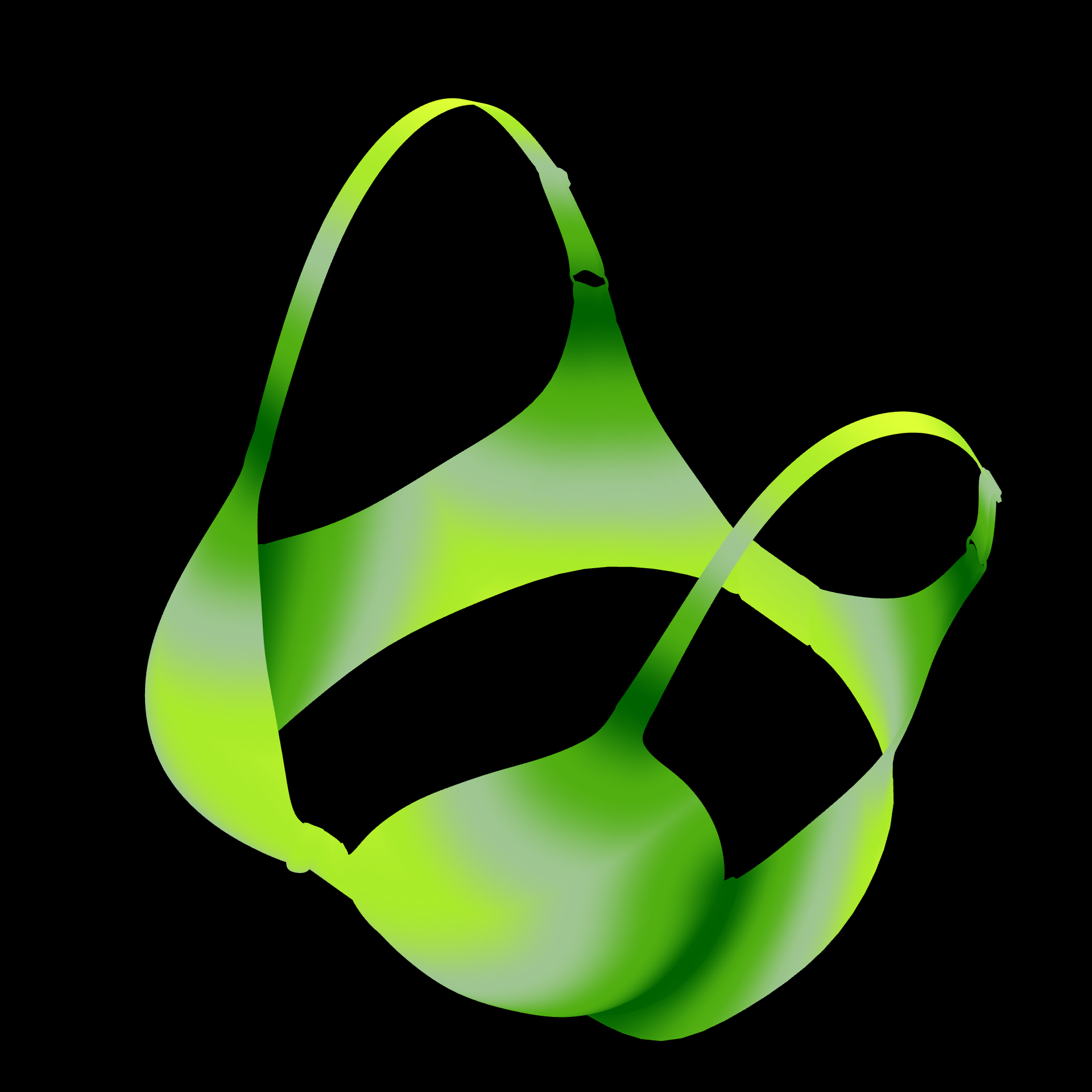

Computation helped trace how small material decisions propagate through the entire system, from wire curvature and channel tension to how loads travel across the cups and band. These simulations exposed failure modes that are invisible in static product views.

ROLE Process Tree Development, Material Teardown, Component Mapping, Systems Research

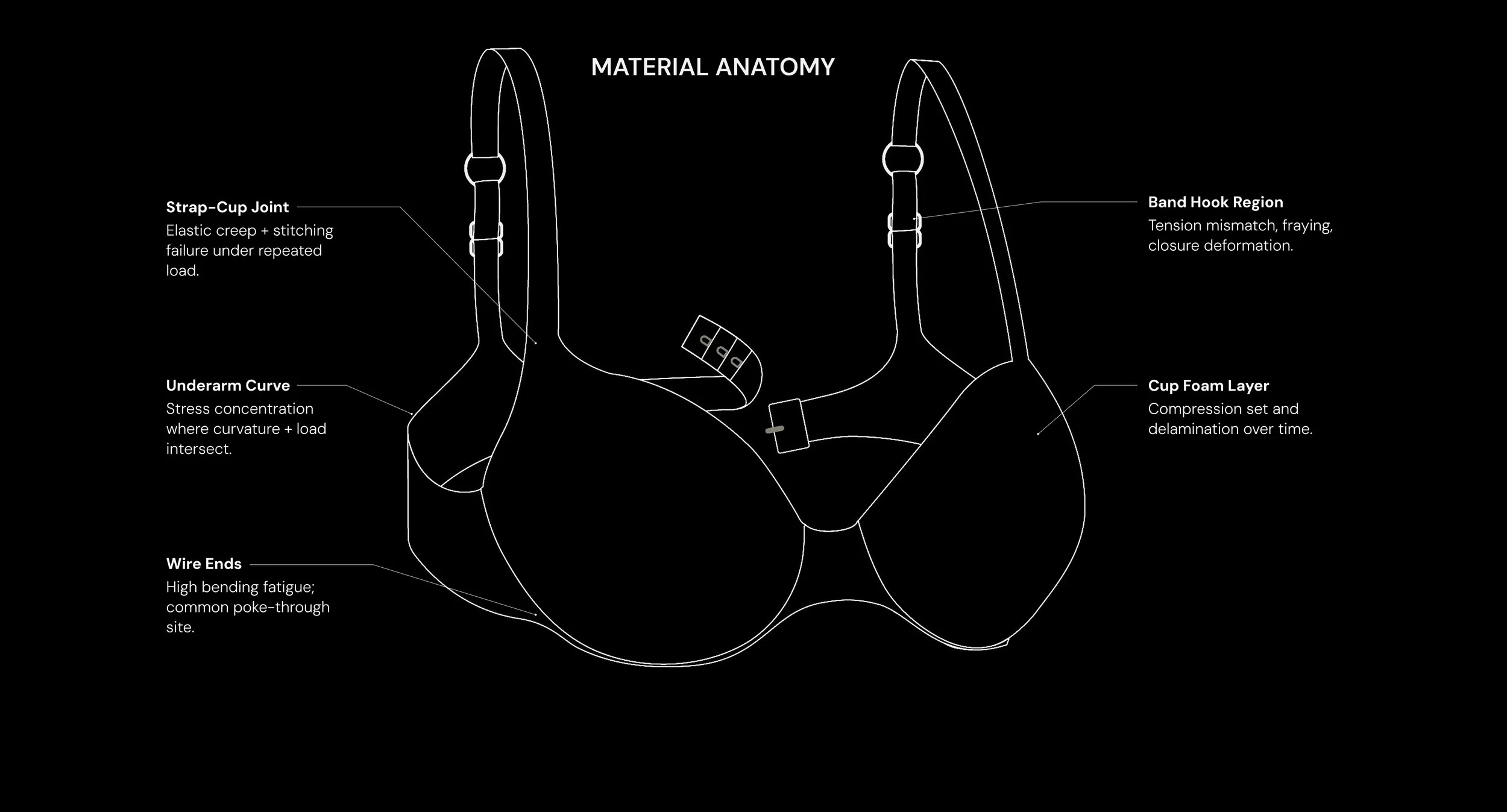

This project investigates the underwire bra as an intimate architecture shaped by material systems, ergonomic forces, manufacturing shortcuts, and cultural expectations. Conventional construction produces recurring pain points. Through a tear down analysis, material analysis, discomfort mapping, and lifecycle assessment, the work reveals hidden infrastructures across extraction, fabrication, wear, and disposal.

Photography by Julia Brière

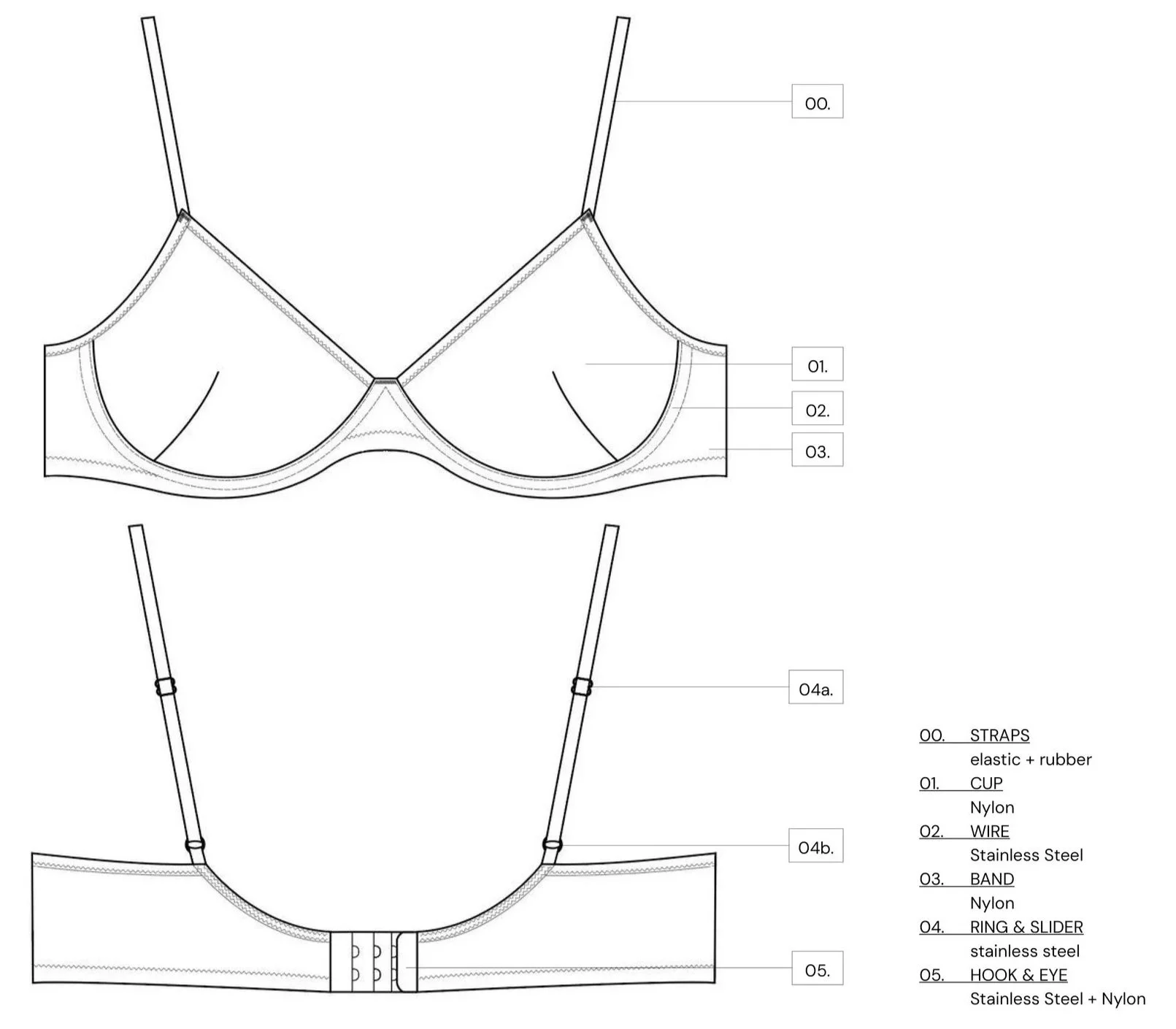

01 MATERIAL BREAKDOWN

Component analysis

Each component carries its own sourcing, processing steps, and durability challenges, shaping the long-term behavior of the garment. This breakdown defines the structural logic underlying subsequent cultural, ergonomic, and computational analyses.

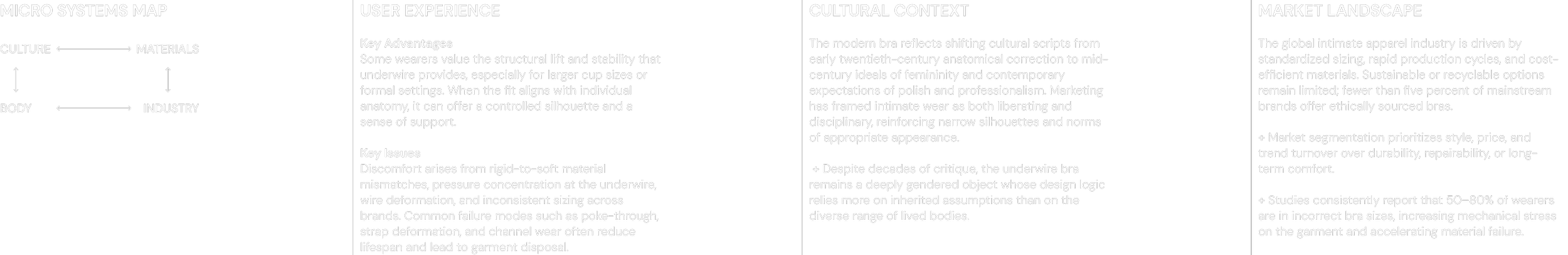

02 SYSTEMS AND CULTURAL ANALYSIS

Utility, bias, and cultural expectations

Intimate wear is shaped by overlapping systems of cultural expectation, industrial logic, material constraint, and embodied pressure. Misalignment between standardized anatomy and lived variation produces discomfort, premature failure, and environmental waste. This analysis frames the underwire bra as a site where material intelligence, design bias, and bodily experience intersect.

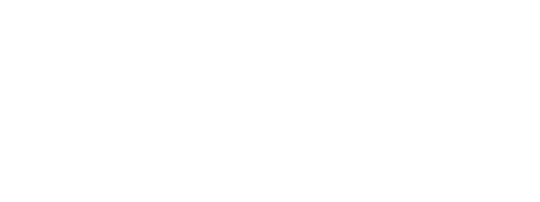

03 HISTORY AND PRODUCTION IMPACT

Production, use and disposal

Across its history, the underwire bra has been optimized for standardized sizing, manufacturing efficiency, and cost, while long term material performance and bodily variation have been deprioritized. Mapping production, use, and disposal reveals how upstream design and manufacturing decisions shape wear patterns, discomfort, replacement cycles, and environmental impact over time.

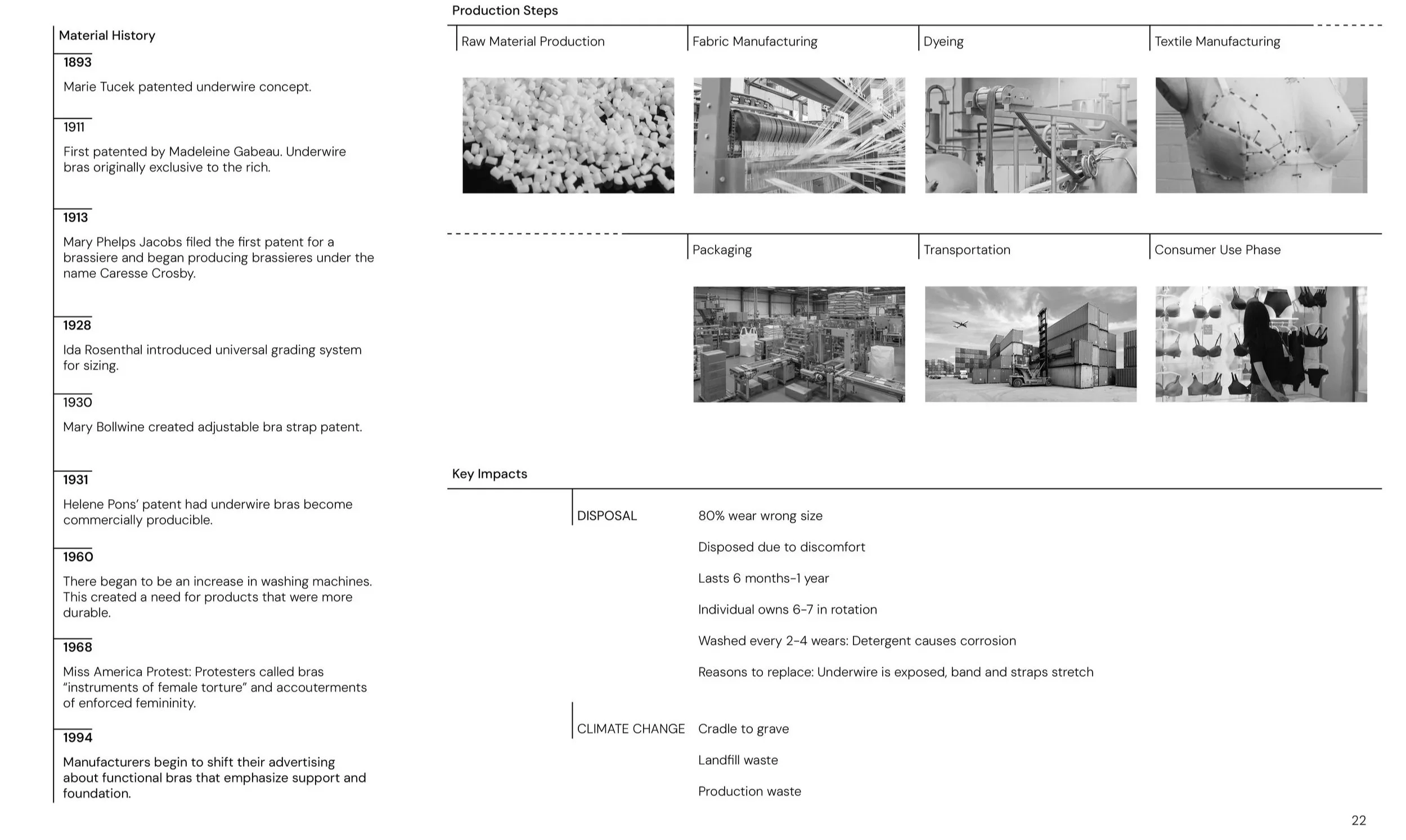

04 ENVIRONMENTAL IMPACT

Process tree

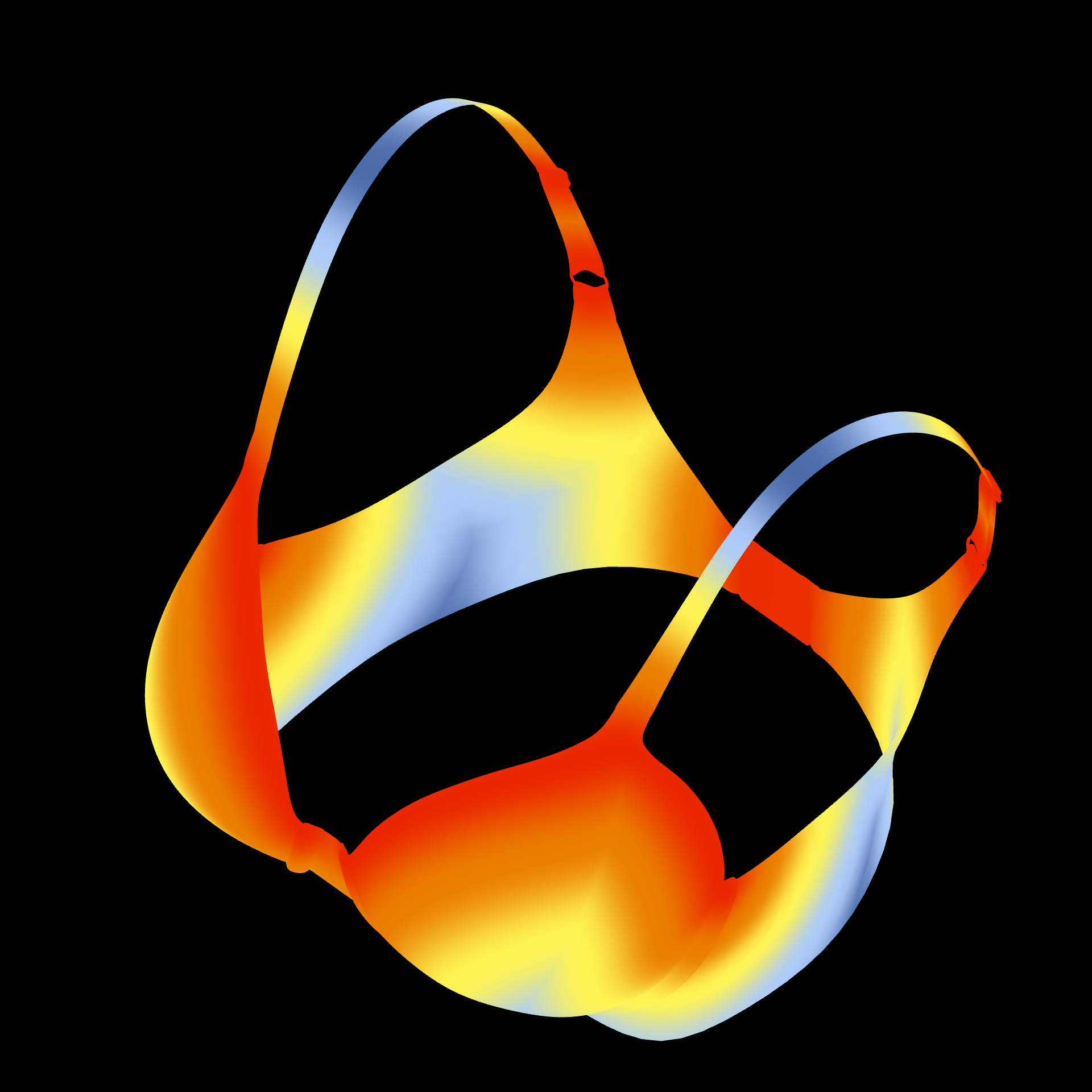

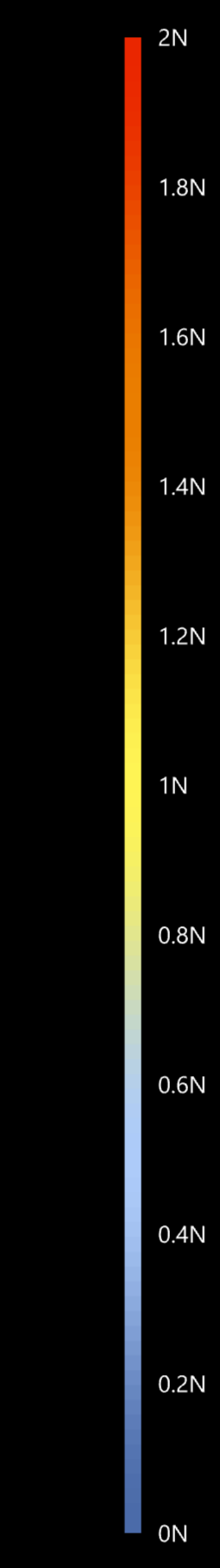

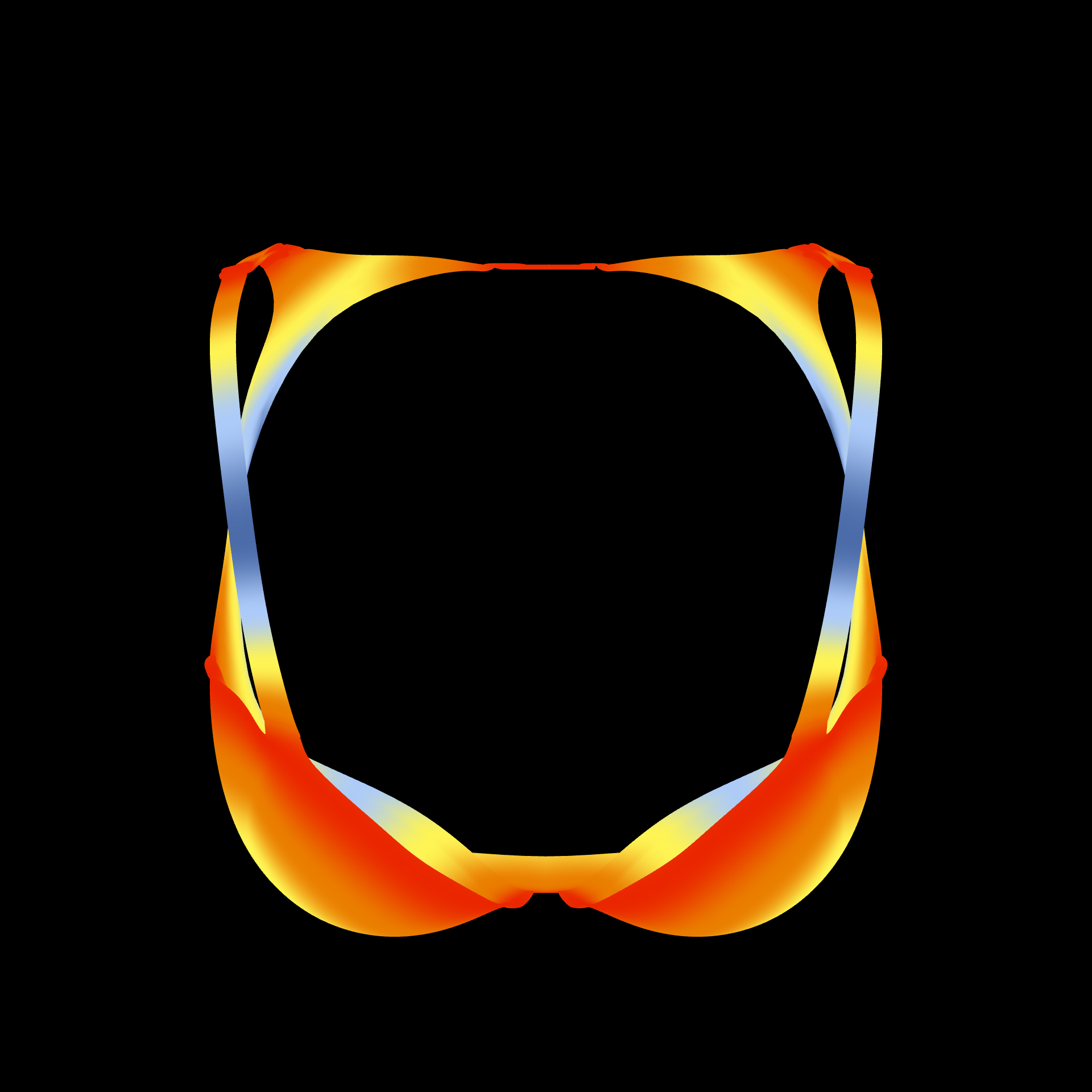

05 COMPUTATION

Visualization mapping

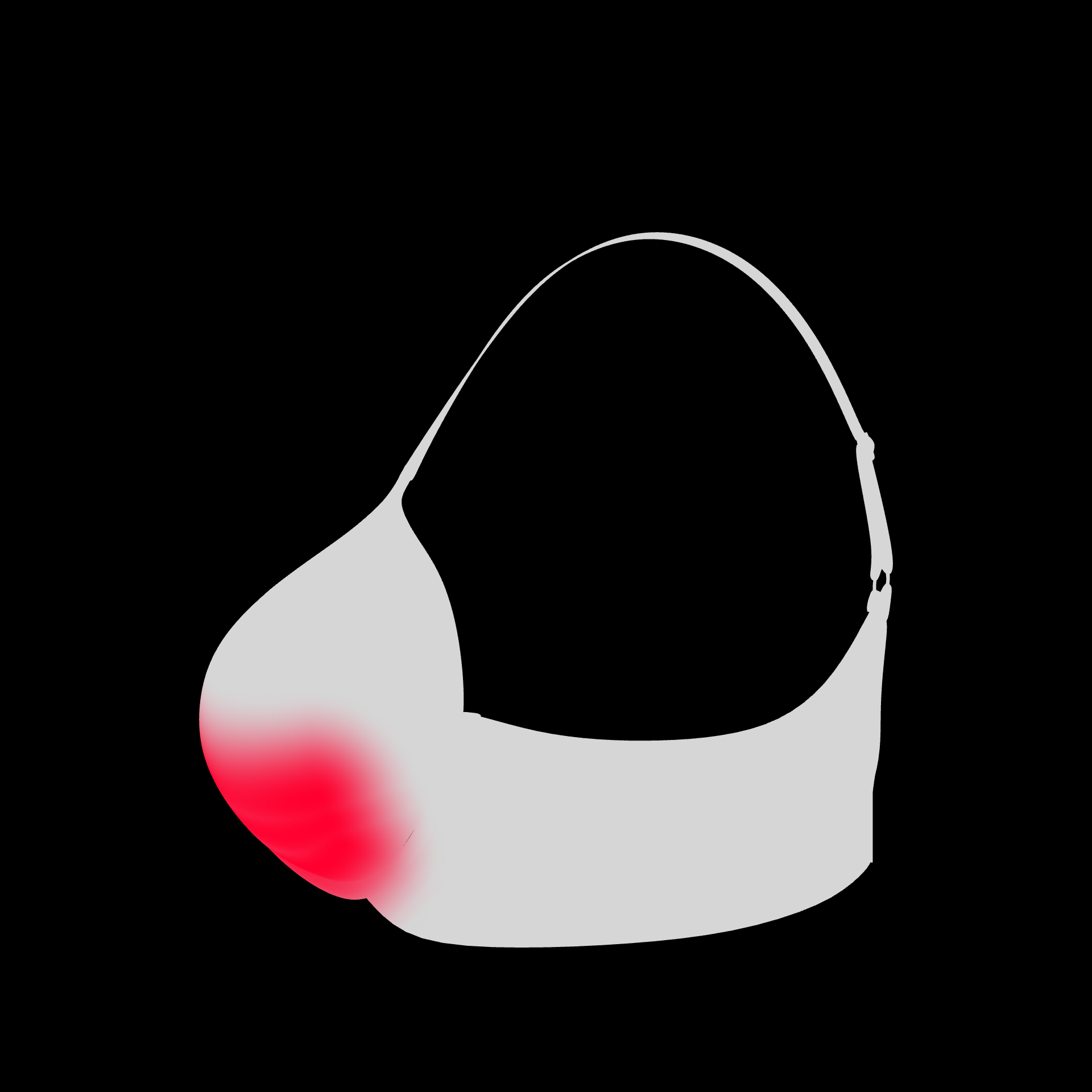

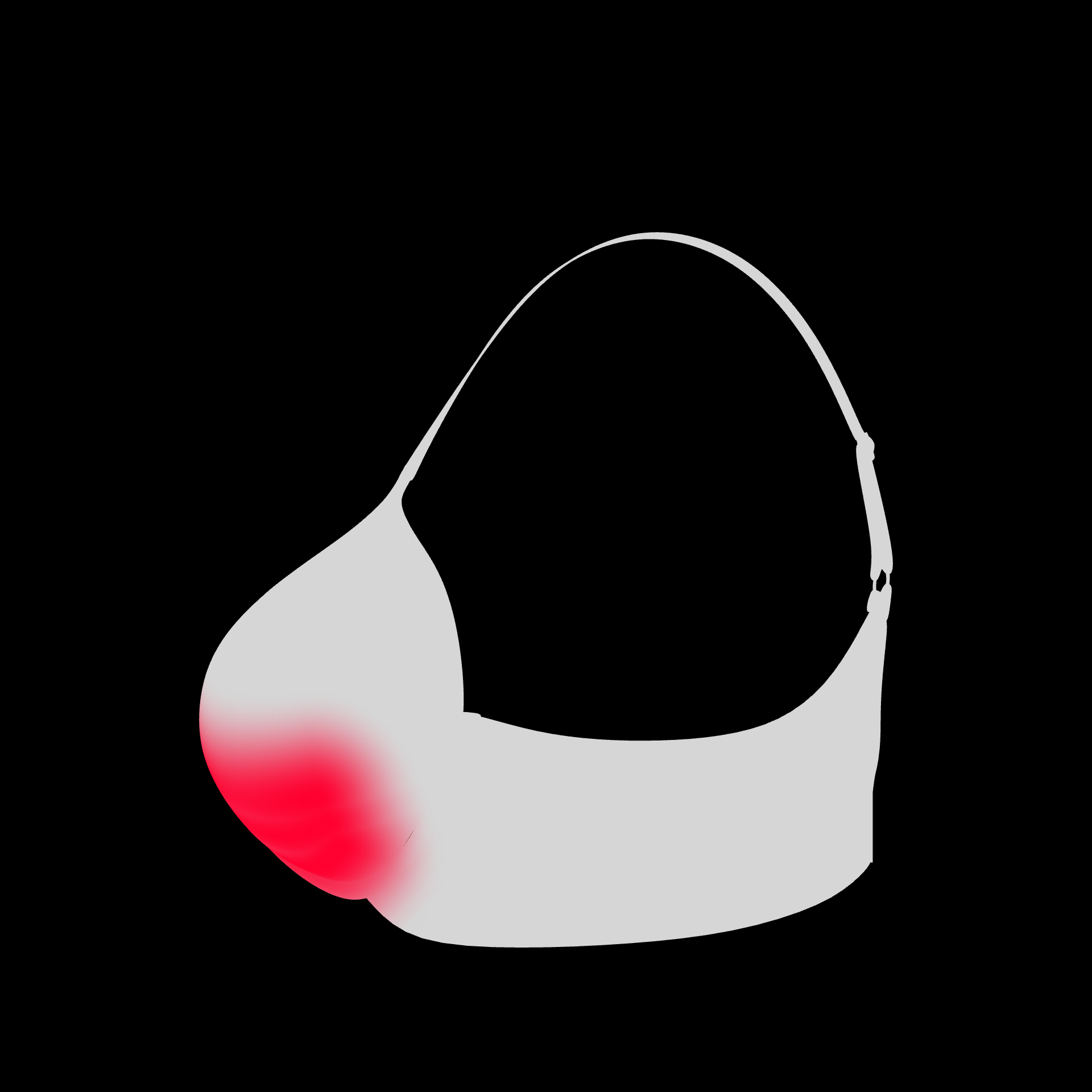

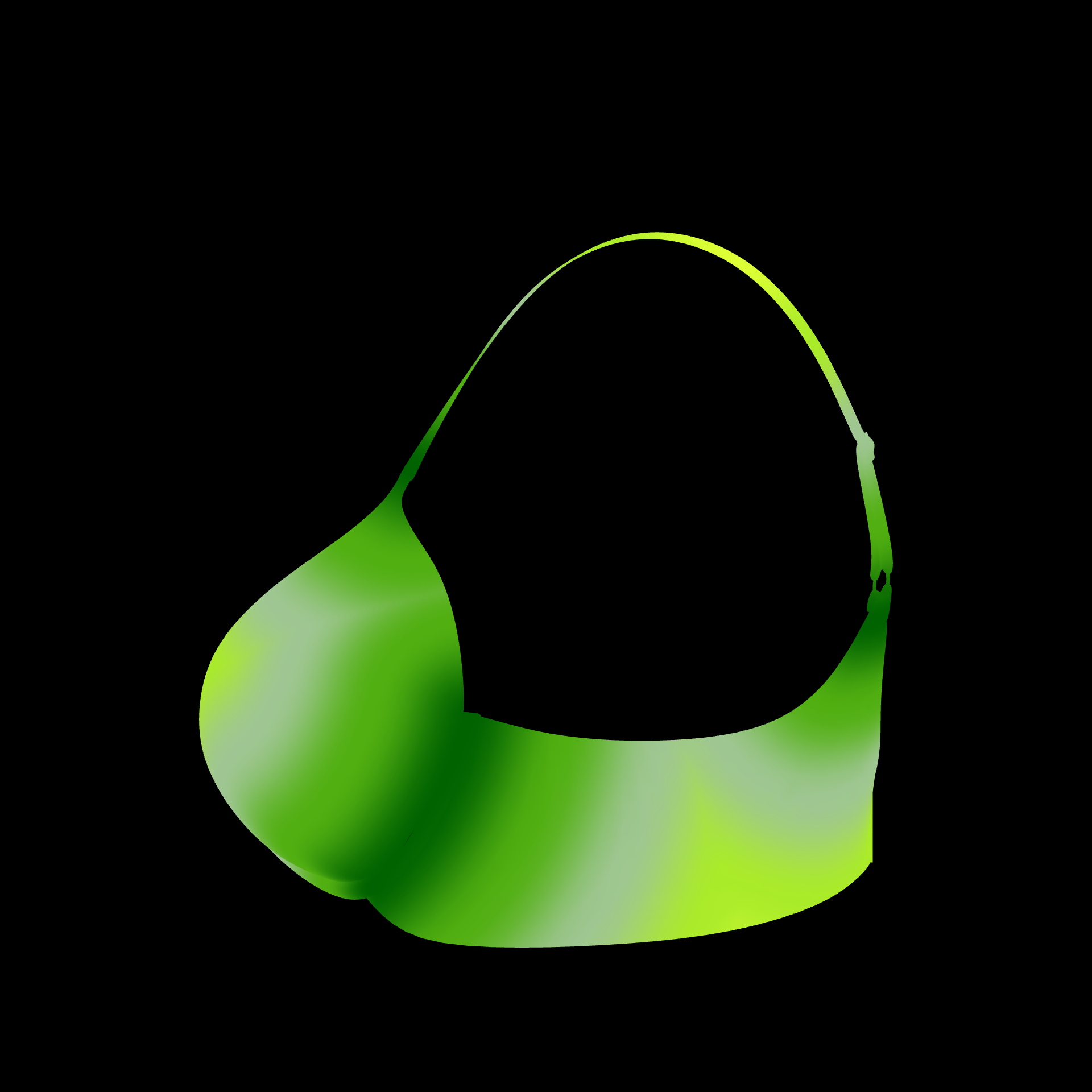

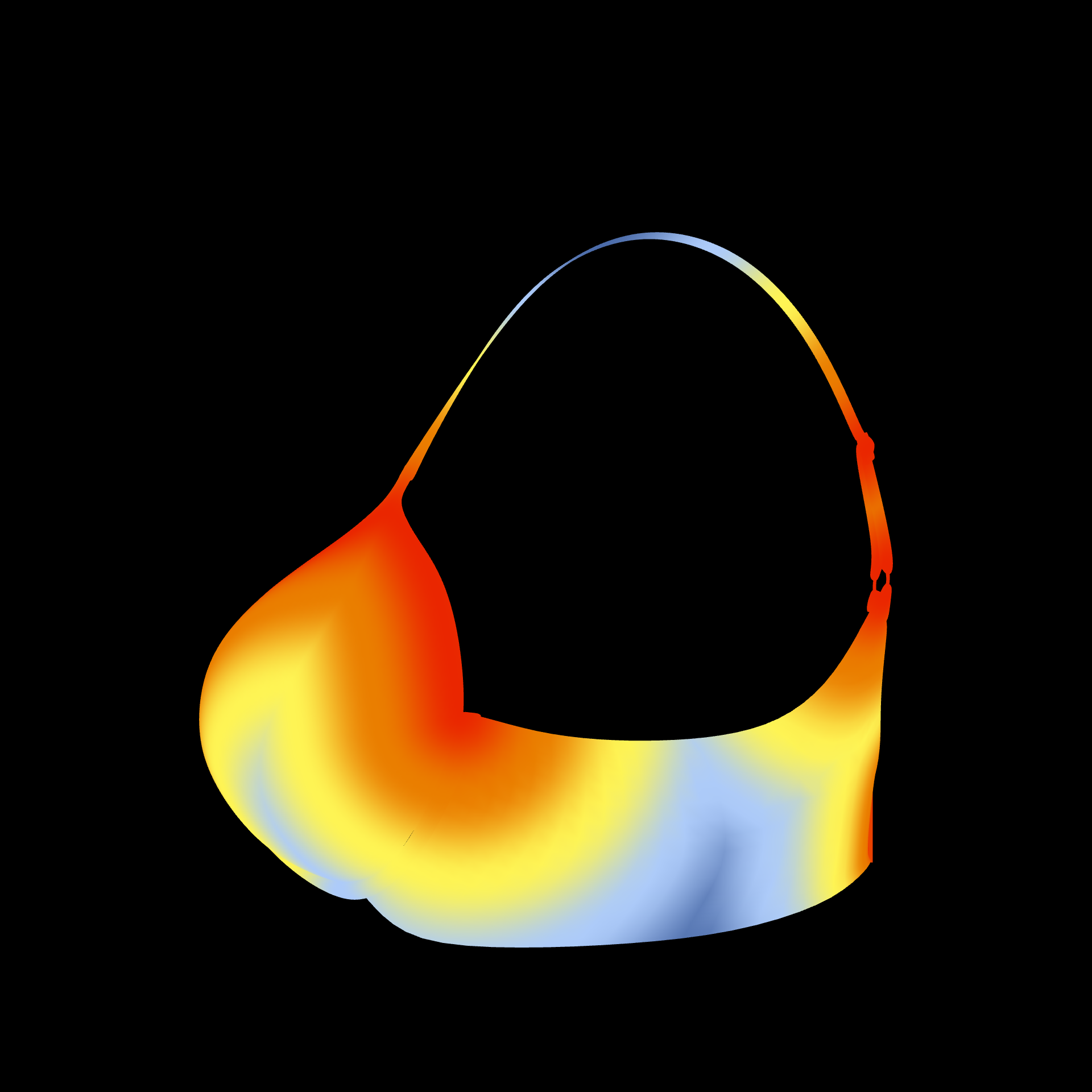

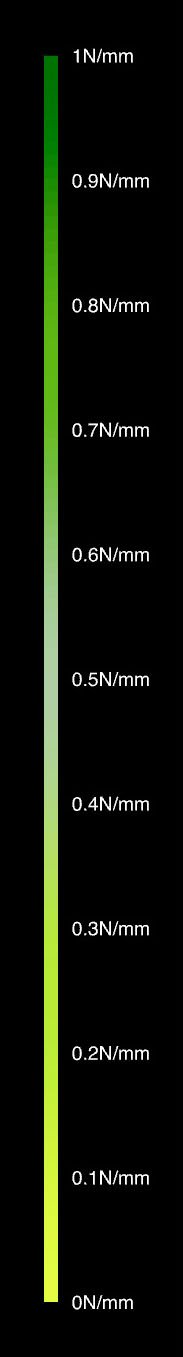

Tear Risk Simulated indicator of regions prone to material failure, derived from curvature, stress concentration, and fabric strain. Identifies locations where repeated loading increases rupture likelihood over time.

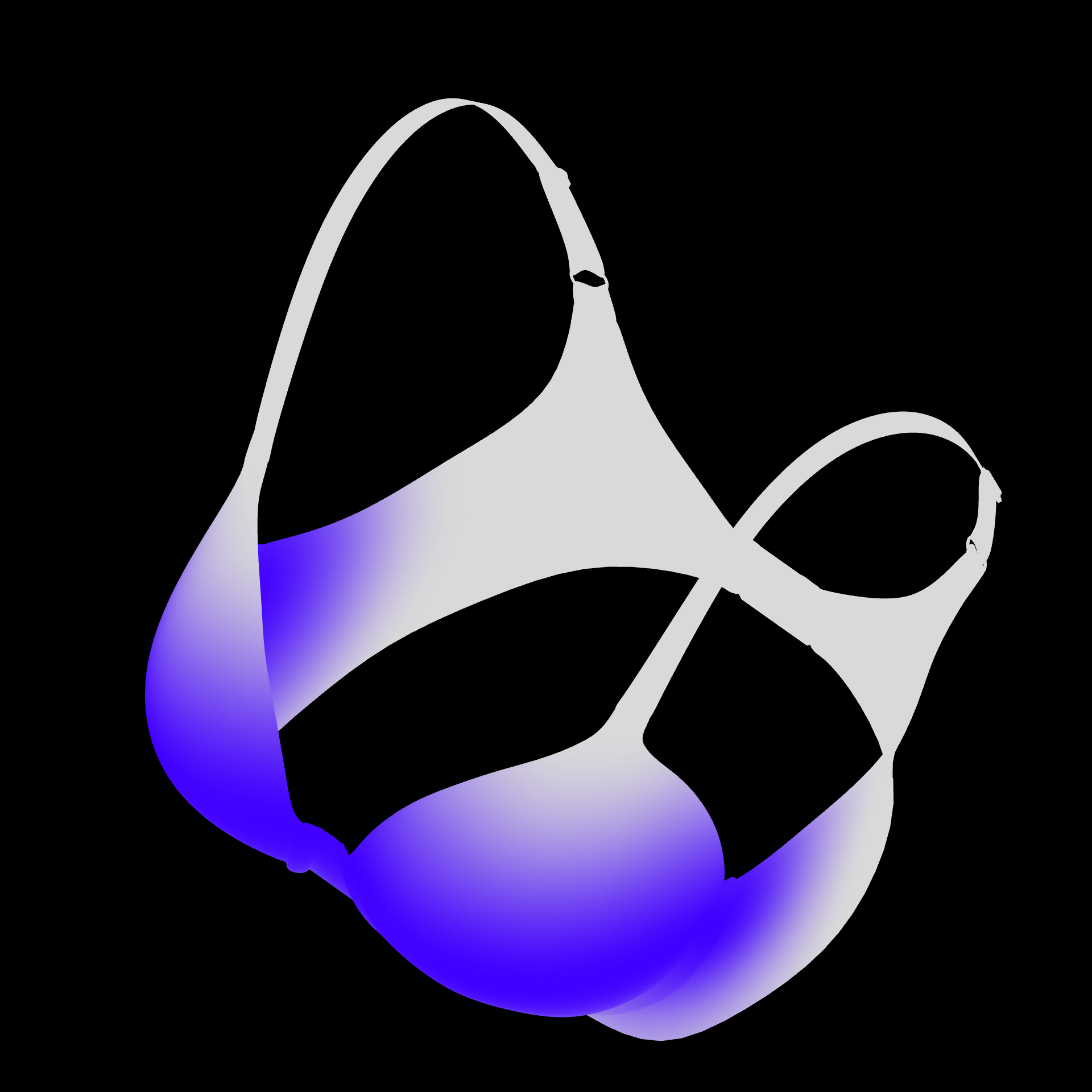

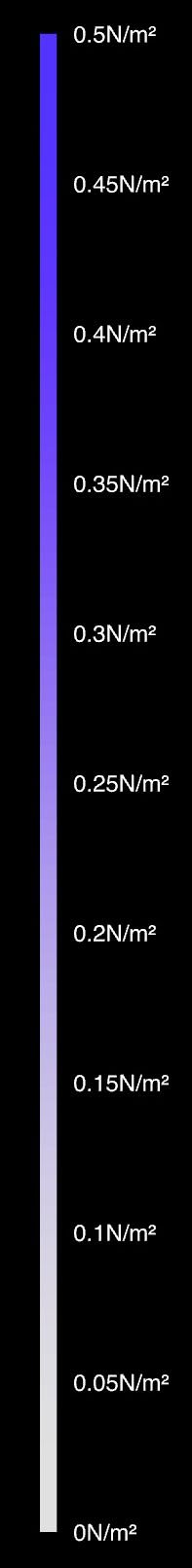

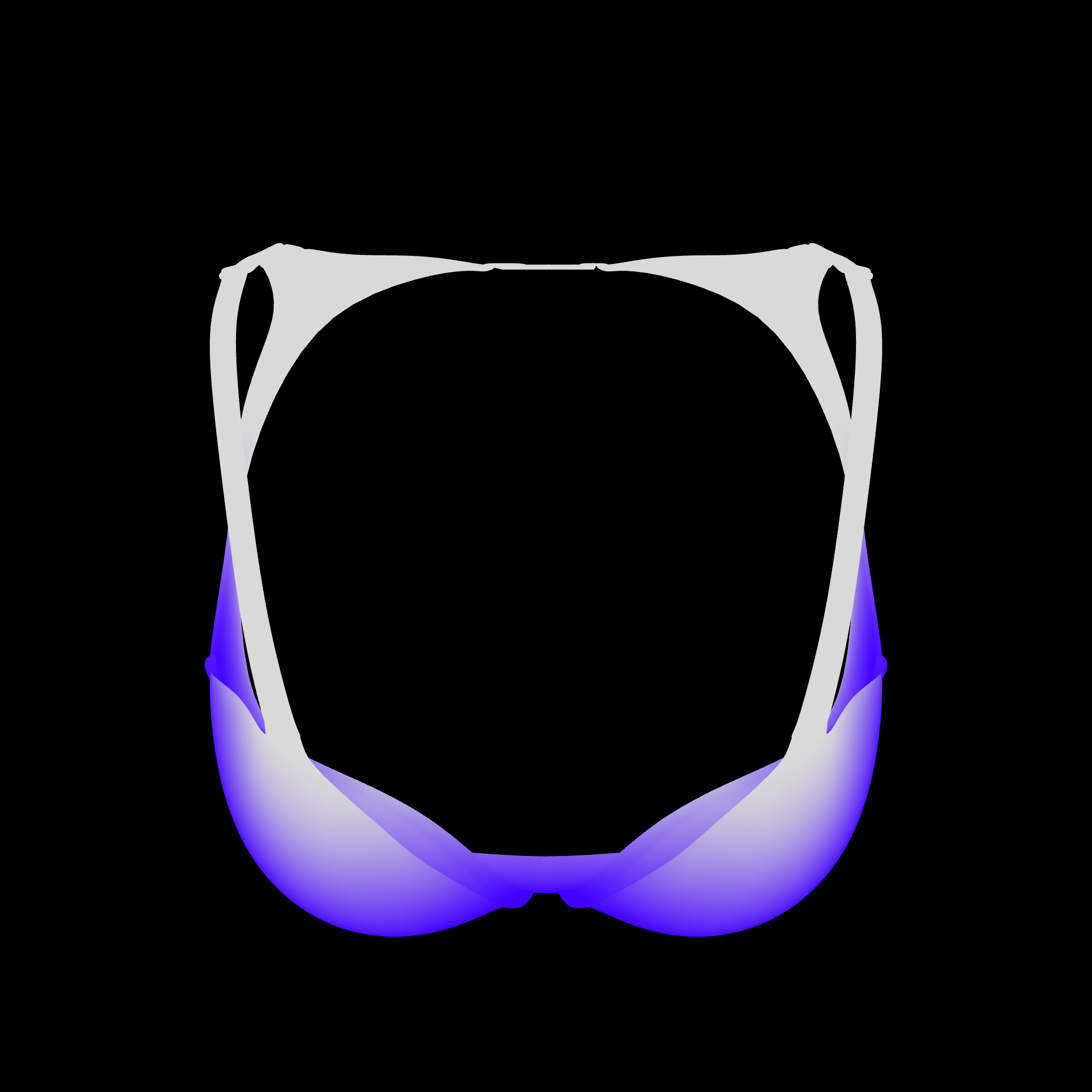

Tension Visualization of force distribution through straps, cups, and band under load. High-tension zones indicate structural stress points affecting fit stability, durability, and support performance.

Simulations represent comparative, not absolute, values based on geometric and material assumptions.

This computational study translates physical interaction into measurable system behavior. The analysis links user discomfort to repeatable mechanical stress patterns produced by standardized geometry, material pairing, and load distribution. The work frames fit failure as a problem rooted in system assumptions rather than individual bodies, positioning computation as a bridge between material performance, human experience, and design decision-making.

Compression Computational estimate of relative compression across the underwire and side band. Highlights regions where geometry and constraint concentrate load, correlating with discomfort and early material fatigue.

Pressure Approximation of contact pressure between garment and body. Elevated values indicate areas associated with discomfort, circulation restriction, and long-term wear patterns.

06 CONCLUSIONS

Synthesis and implications

This project reframes the underwire bra as a material system shaped by cultural norms, industrial constraints, and embodied experience. By combining material breakdown, lifecycle analysis, and computational mapping, the work surfaces consistent patterns of stress, failure, and discomfort that extend beyond individual products or brands.

This research positions intimate wear as a site where material intelligence, computation, and cultural bias intersect. It proposes material behavior as both a technical and social signal, opening pathways for future work in adaptive structures, embodied sensing, and non-standardized design systems.

Key Findings

Standardized underwire curvature produces predictable stress concentrations at the underarm and wire ends, regardless of brand or price point.

Mis-sizing is not a user error but a systemic outcome of grading systems optimized for manufacturing efficiency rather than anatomical diversity.

Rigid-soft material pairings amplify compression and fatigue at interfaces, accelerating material degradation and discomfort.

Regions identified through computational stress mapping align closely with reported user pain points, reinforcing lived experience as a valid form of material data.

Cultural expectations around lift, silhouette, and professionalism directly inform material choices that prioritize visual conformity over adaptive fit.

Emerging Research Questions

How might intimate garments be designed to adapt their structure to individual anatomy rather than standardized sizing systems?

What alternative material behaviors could replace rigid corrective elements with systems that yield, redistribute load, or reconfigure over time?

How could sensing or computation be embedded to make material fatigue and stress visible before failure occurs?

What would it mean to define fit through load distribution and comfort thresholds rather than measurements alone?

How might cultural expectations around support and appearance need to shift to enable more responsive material systems?