AVOCADO SEED BIOPLASTIC

Material exploration using food waste to create bioplastics

2020 | Academic | Independent project

AWARDS Pratt Material Lab Prize, Third Place, August 2020

PUBLICATIONS | FEATURES “Pratt Students Convert Everyday Waste into Viable Products and Materials” Metropolis Magazine, September 2020 ”Avocado Pit Bioplastic” Materiom, February 2020 ”Avocado Pit Composite” Materiom, February 2020

This material driven project explores how avocado pits can be transformed from food waste into bioplastics. Discarded pits typically end up in landfills, where their slow decomposition releases methane. The work develops and tests methods for stabilizing and casting avocado-based bioplastics, documenting how changes in recipe affect flexibility, translucency, strength, and surface finish.

ROLE Concept Development, Material Research, Formulation Testing, Prototyping, Performance Testing

Photography by Julia Brière

The recipes and samples function as an open material library that connects food waste to circular production. Published open source on Materiom, the recipes have since been adapted by others into new iterations and used as an educational tool for teaching sustainable material development.

01 MATERIAL RESEARCH

Step 1 | Thermal Treatment Bake whole pits at 200°F for two hours to remove moisture and sterilize.

Step 2 | Granulation Break down pits into coarse fragments using a blender.

Step 3 | Refinement Re-bake and mill again to create fine powder with consistent particle size.

Material breakdown and refinement

To create a repeatable, measurable substrate, a controlled method was developed for converting whole pits into fine powder. This process ensures consistency across experiments. The resulting powder is the core variable in the process, influencing color, surface texture, density, and structural behavior.

02 FABRICATION

Bioplastic formulation

Refined avocado pit powder served as the base for each bioplastic recipe. By varying the ratios of water, glycerin, gelatin, and powder, a series of samples was produced to test how small formulation changes affect drying and curing behavior. The results informed a repeatable, scalable recipe.

05 MATERIAL TESTS

Prototypes

A series of hand-cast samples, molded forms, and test sheets was produced to evaluate bioplastic behavior across different thicknesses and geometries. These prototypes revealed how the material can deform, shrink, and form surfaces with varied tactile characteristics.

Samples with increasing avocado-powder content were tested for strength and elasticity. Left to right: 1 tbsp, 2 tbsp, 3 tbsp.

06 MATERIAL BEHAVIOR STUDY

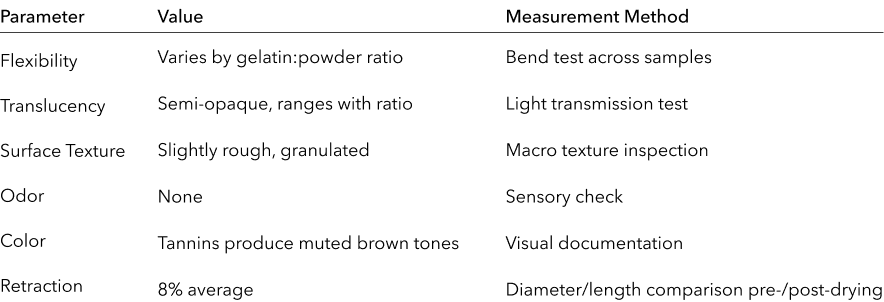

Flexibility, translucency, surface texture, odor, color, and dimensional change were recorded. Methods included bend tests, light transmission measurements, tactile inspection, and shrinkage comparisons before and after drying.